We are a leading magnetic assembly manufacturer offering customized magnetic solutions tailored to meet the demands of diverse industries such as automotive, electronics, medical devices, and industrial machinery. Our magnetic assemblies integrate high-grade permanent magnets (Neodymium, Ferrite, Alnico, or SmCo) with precision-engineered housings, metal parts, or plastic components to ensure optimal magnetic performance, mechanical stability, and long-term durability. We support OEM/ODM projects with comprehensive services from design, prototyping to mass production. Our products are widely used in sensors, motors, magnetic filters, loudspeakers, and holding systems. Quality and innovation are at the core of our manufacturing process.

Features

High Magnetic Strength

Utilizes high-performance magnets (NdFeB, SmCo, Ferrite, etc.) for strong and reliable magnetic force.

Custom Design Flexibility

Supports a wide range of shapes, sizes, and configurations tailored to your application needs.

Durable Construction

Integrated with metal or plastic housings to ensure long-lasting mechanical strength and environmental resistance.

Precision Assembly

Manufactured with tight tolerances and quality control to ensure consistent performance and easy integration.

Wide Application Range

Ideal for use in motors, sensors, holding systems, magnetic tools, filtration devices, and electronic equipment.

Advantages

Strong Magnetic Performance

Delivers high magnetic force with stable output, ensuring reliable functionality in demanding applications.

Custom Engineering Solutions

Tailor-made designs to meet specific technical and structural requirements across various industries.

High Durability and Stability

Built with robust materials and advanced bonding techniques for excellent resistance to heat, corrosion, and mechanical stress.

Cost-Effective Production

Optimized design and manufacturing processes reduce cost while maintaining high quality and performance.

Versatile Application Compatibility

Compatible with a wide range of devices and systems, including motors, sensors, filters, and magnetic tools.

Application

1. Automotive Industry

High-temperature resistance and vibration durability ensure stable performance in engines, sensors, and braking systems.

Custom-fit designs for compact integration into EV motors, ABS systems, and actuators.

2. Medical Devices

Biocompatible and corrosion-resistant coatings suitable for use in MRI machines, pumps, and diagnostic equipment.

Precision assemblies ensure high reliability in critical applications.

3. Consumer Electronics

Miniaturized magnetic assemblies ideal for speakers, smartphones, and wearable devices.

Excellent magnetic consistency for smooth and efficient operation in compact spaces.

4. Industrial Equipment

Strong holding force and rugged construction for use in magnetic lifters, filters, and automation tools.

Long service life in harsh environments with exposure to dust, oil, and mechanical impact.

5. Renewable Energy and Motors

High-performance rare earth magnets (NdFeB, SmCo) enable efficiency in wind turbines and electric motors.

Custom magnet alignment enhances torque and energy conversion.

FAQ

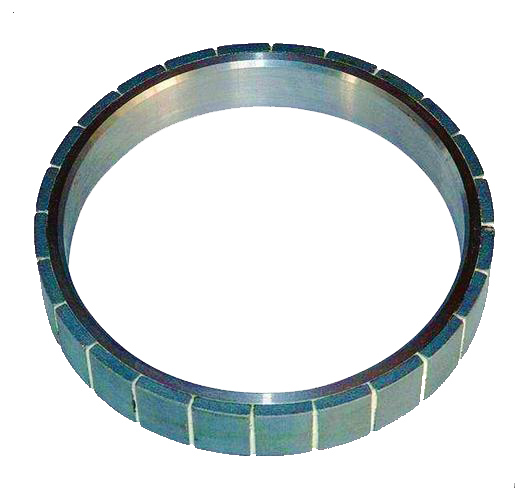

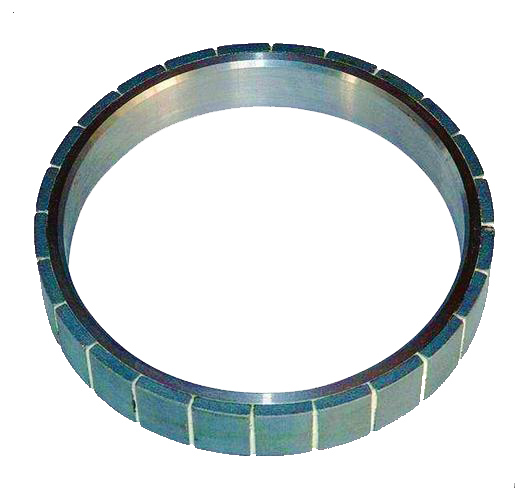

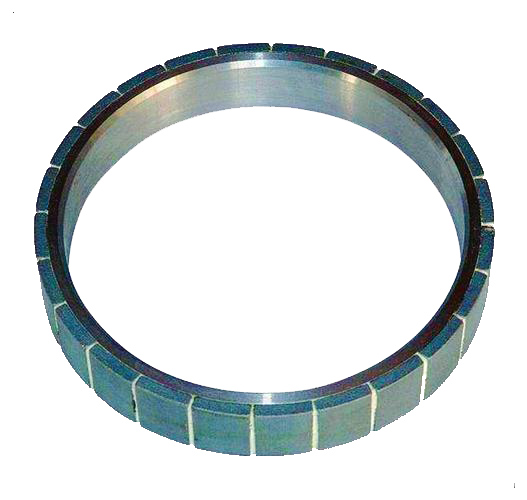

1. What is Magnetic Circular Assembly?

Magnetic Circular Assembly (MCA) is a manufacturing technique where components self-align into circular structures using magnetic forces, enabling precise and efficient assembly.

By leveraging programmable magnetic fields, MCA reduces manual intervention, speeds up production, and ensures high repeatability in robotics and micro-fabrication.

Key sectors include electronics (PCB assembly), medical devices (implant fabrication), and aerospace (modular satellite components).

Yes! MCA excels in micro- and nano-assembly, using tailored magnetic fields to manipulate tiny parts without physical contact.

MCA minimizes material waste and energy use by enabling reversible assemblies and reducing adhesive/mechanical fasteners.